Printer mainboards are one of the most misunderstood components inside modern inkjet printers. When something goes wrong, it’s tempting to “bridge,” “short,” or bypass a failed fuse just to see if the printer powers back on. Unfortunately, that approach often causes far more damage than the original problem.

This instructional guide explains what actually happens when printer mainboard fuses are mishandled, why certain shortcuts lead to cascading failures, and how careful board-level techniques can prevent permanent damage. The information is intended for educational and learning purposes, especially for those interested in electronics repair, sustainability, and reducing e-waste.

Why Printer Mainboards Fail in the First Place

Mainboards manage power distribution, logic control, and communication across the entire printer. To protect sensitive components, manufacturers place small surface-mount fuses at key power entry points.

When a fault occurs downstream—such as a shorted component or power surge—the fuse is designed to fail first. This prevents damage from spreading to power regulation circuits, processors, and voltage control components.

A blown fuse is not the problem itself; it is a symptom that something else needs to be investigated.

The Hidden Danger of Shorting a Fuse

One of the most common mistakes in DIY electronics repair is intentionally shorting a blown fuse “just to test.” While this may appear harmless, it removes the only protection the board has.

Shorting a fuse can send uncontrolled current into sensitive areas of the board. This often leads to overheated capacitors, damaged processors, and failures that are no longer visible or repairable.

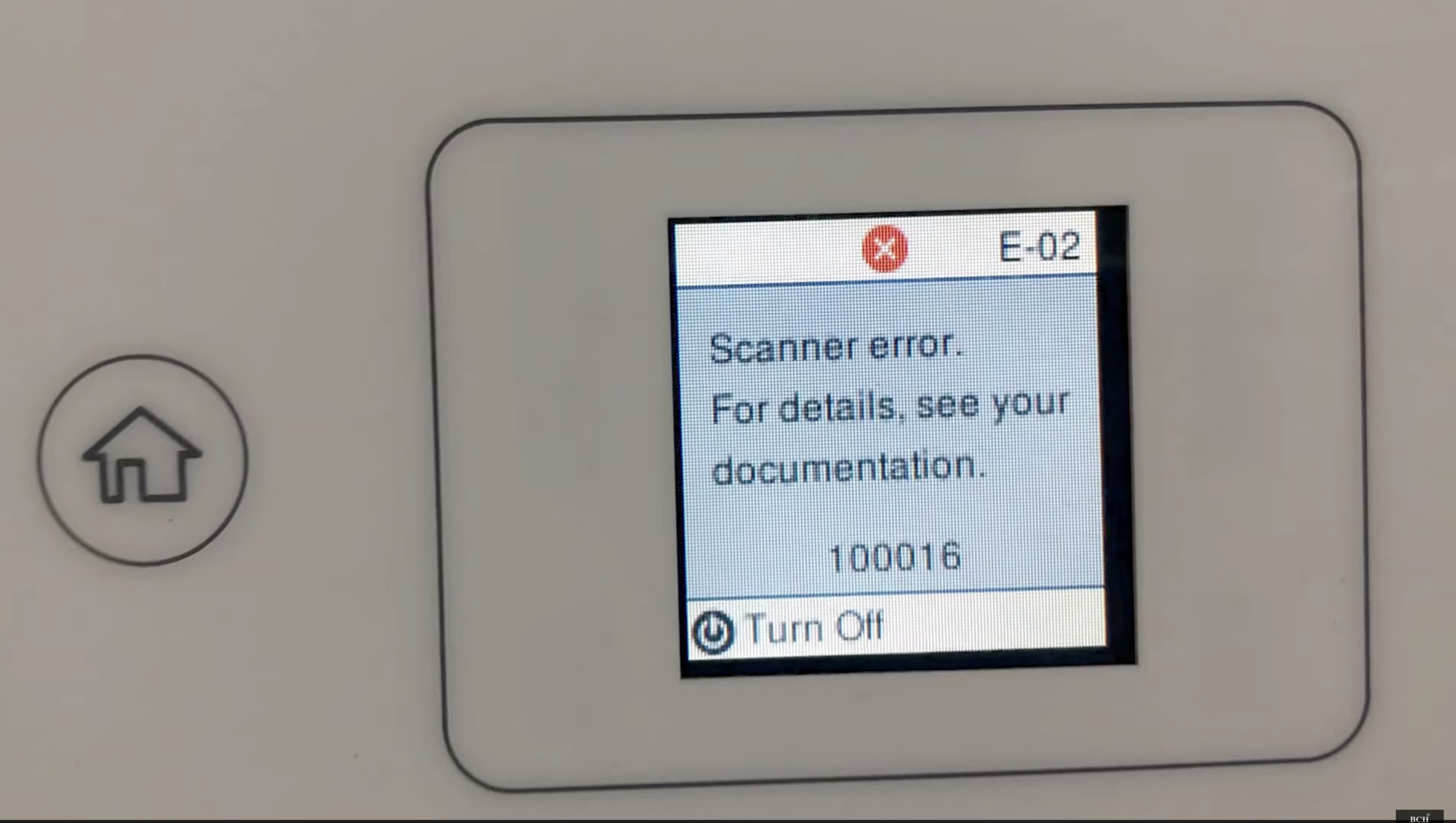

In the instructional demonstration, bypassing a fuse caused downstream components to overheat, illustrating why this shortcut almost always makes the situation worse.

The key lesson is simple: a fuse should never be bypassed. It should only be replaced after the original cause of failure is understood.

Proper Fuse Removal and Board Cleanup Techniques

When excessive solder or incorrect materials are used, removing or replacing a fuse becomes difficult. The video highlights several best-practice techniques commonly taught in board-level repair training.

Flux plays a critical role by lowering solder melting temperature and improving heat transfer. When solder does not flow correctly, adding more flux often resolves the issue immediately.

Using short lengths of solder wick is also important. Long strips draw heat away from the work area, making it harder to reach proper temperature where the solder joint is located.

Another counterintuitive but effective technique is adding fresh solder to help remove old solder. This allows for deeper and cleaner removal without damaging pads or traces.

Why Correct Fuse Installation Matters

Installing a surface-mount fuse requires careful alignment and controlled heat. One side of the fuse is typically anchored first, followed by precise placement and soldering of the second side.

Excessive heat, pressure, or misalignment can weaken solder pads or introduce new electrical faults. Proper technique ensures the fuse performs its protective role as intended.

Testing Power Rails After a Fuse Failure

Even after a fuse is replaced, the board must be tested before full operation. A blown fuse may indicate deeper issues such as shorted capacitors or failed voltage regulators.

In the demonstration, power rails were tested to confirm stability before fully powering the board. This step is essential to prevent repeated failures and protect newly installed components.

Skipping this testing phase often results in additional damage that could have been avoided.

Learning from Repeated Board Damage

The second board shown in the video demonstrates another important lesson: missing components are just as dangerous as shorted ones. Removing fuses without replacing them leaves circuits incomplete and unpredictable.

For learners and hobbyists, this reinforces a core principle of electronics repair: every protective component exists for a reason.

Repair Education and E-Waste Reduction

Understanding how and why printer mainboards fail helps reduce unnecessary electronic waste. Many boards are discarded simply because a protective component failed and was handled incorrectly afterward.

By learning why fuses blow, how to replace them correctly, and how to test downstream circuits, more electronics can be repaired, reused, or responsibly recycled instead of discarded.

Watch the Full Instructional Demonstration

The embedded video walks through real-world examples of fuse mistakes, proper cleanup, replacement techniques, and testing procedures. It provides visual clarity for concepts that are difficult to convey through text alone.

This content is presented for instructional viewing and educational discussion.

Educational Disclaimer

This article and the accompanying video are provided for educational purposes only. Board-level electronics repair involves risk and should only be attempted with proper training, tools, and safety precautions.